What can floating photovoltaics bring?

Reading time: 2 minutes

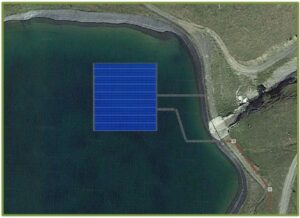

Design project for a floating photovoltaic installation on the snowmaking pond of Espot Esquí

En el marc del projecte PSTD Bike Natura-Aventura, impulsat pel Consell Comarcal del Pallars Sobirà i cofinançat a través dels fons europeus Next Generation EU, hem desenvolupat el disseny tècnic d’una instal·lació fotovoltaica flotant per autoconsum sobre la bassa d’innivació “Els Estanyets”, ubicada dins el recinte de l’estació d’Espot Esquí, a 2.120 metres d’altitud.

Aquesta proposta s’inclou dins l’actuació 5 “Fotovoltaica flotant pistes d’esquí”, en el marc de l’eix 2 “Millora de l’eficiència energètica” del Pla de Sostenibilitat Turística en Destinacions (PSTD). L’objectiu és promoure noves solucions energètiques sostenibles en entorns d’alta muntanya, aprofitant infraestructures existents i reduint la petjada ambiental de les instal·lacions turístiques hivernals.

Advantages of floating photovoltaics in high mountain environments

The installation of photovoltaic fields on water surfaces offers various technical and environmental advantages:

• Optimization of land use, especially in protected natural environments where landscape and territorial impact is critical.

• Improvement in solar panel efficiency due to the cooling effect of the water, which reduces operating temperature and increases electrical performance.

• Reduction of water evaporation from the pond and limitation of algae growth.

• Functional integration with existing infrastructures, such as snowmaking ponds.

These types of installations are especially relevant in the current context, where, after a prolonged period of drought, recent rains have allowed the recovery of water reserves in many reservoirs and ponds across the country.

This scenario reinforces the need to propose complementary and sustainable uses of these water resources, such as renewable electricity generation with zero direct emissions.

The project foresees the installation of rows of horizontal photovoltaic modules, placed on a floating structure specifically designed for extreme snow and wind conditions. Although they may be subject to change, the following preliminary points have been defined:

- Minimum available pond area

- Floating structure capable of supporting the snow loads at this altitude, with an associated maintenance protocol to ensure the correct operation of the installation. South orientation and placement of the solar field in the area with the most sunlight, minimizing shadows.

- High-efficiency monocrystalline (mono-PERC) photovoltaic modules with a product warranty of ≥ 15 years.

- Inverters with multiple MPPTs to optimize energy capture.

- Voltage drop < 3%, with wiring designed to adapt to the varying water levels of the pond.

- Technical and access walkways integrated into the floating island itself to facilitate maintenance.

- Flexible anchoring with adjustable tensioners to adapt to water level changes.

- Provision of a technical room to house inverters and electrical protection equipment

Characteristics of the floating structure

The support structure is based on panel floaters made of HDPE (high-density polyethylene) with UV protection, which provide a fixed inclination of 15º for the modules. Each module rests on three floaters, ensuring a buoyancy of 66 kg/m² and a separation that allows natural panel ventilation.

The support structure is based on panel floaters made of HDPE (high-density polyethylene) with UV protection, which provide a fixed inclination of 15º for the modules. Each module rests on three floaters, ensuring a buoyancy of 66 kg/m² and a separation that allows natural panel ventilation.

Additionally, the design includes maintenance floaters with a rough anti-slip surface to allow safe movement of technical personnel, as well as a walkway from the edge of the pond to the central floating island.

This project exemplifies the potential of floating photovoltaics as an innovative and replicable solution, particularly in high mountain areas where environmental compatibility is key. The design addresses both structural and operational requirements, ensuring a safe, efficient, and integrated installation within the environment.

As water resources recover, and in the context of the urgent energy transition, it is essential to leverage synergies between energy and territory to generate added value and move towards more intelligent and sustainable resource management.

Key Challenges of Photovoltaics: Causes, Impact, and Prevention

Key Challenges of Photovoltaics: Causes, Impact, and Prevention

When a photovoltaic installation operates optimally, ensuring a safe and reliable electricity supply, it can become a large-scale power source. However, photovoltaic technology faces major daily challenges in terms of quality, installation, operation, and decommissioning. Below, we describe five main challenges facing photovoltaic technology:

Derating

What is Derating?

Derating refers to the power reduction in photovoltaic inverters caused by environmental factors such as heat, altitude, and voltage. In extreme situations, this phenomenon can even stop production. This effect is especially noticeable in areas with high temperatures.

Causes of Derating

The main causes of derating are:

- Temperature: When inverters generate heat while converting direct current (DC) into alternating current (AC) and the ambient temperature is high, the inverters reduce their power to protect internal components.

- Altitude: At high altitudes, the low air density facilitates ionization at high voltages, affecting inverter performance.

- DC voltage: Maintaining the proper operating voltage range is essential to avoid derating.

How to Prevent Derating

To avoid it, several actions can be taken:

- Proper installation: Follow the manufacturer’s recommendations for ventilation and avoid direct sun exposure.

- Quality of equipment: Choose high-quality inverters with efficient ventilation systems, either by convection or forced ventilation.

- Regular monitoring: Conduct periodic inspections to ensure optimal performance.

LID Effect (Light-Induced Degradation)

What is the LID Effect?

The LID effect refers to the degradation of photovoltaic modules caused by chemical reactions in silicon cells, leading to a loss of power and efficiency during the first months of solar exposure. This can result in a reduction of up to 10% of the initial power.

Causes of the LID Effect

The main cause of this effect is the reaction of boron with elements such as oxygen, iron, or copper present in the silicon cell. While boron is crucial for generating electricity, these reactions reduce electron flow, affecting the module’s efficiency.

Monocrystalline P-type modules are especially vulnerable to LID due to the difficulty in completely eliminating oxygen during the manufacturing process. In contrast, N-type cells, doped with phosphorus, show greater resistance to this effect.

How to Prevent the LID Effect?

- Applying high temperatures and currents.

- Using advanced technologies such as lasers or LEDs.

- Eliminating oxygen within the cell, though this is costly.

- Replacing boron with gallium.

Hotspot

What is a Hotspot?

A hotspot is a localized area within a photovoltaic module that overheats, potentially damaging the module or, in extreme cases, causing a fire. This issue arises from high resistance in a specific area, turning it into an electricity consumer that generates heat, exceeding 200°C.

Causes of Hotspots in Photovoltaic Modules

Hotspots can be caused by internal defects, shading, broken solder joints due to poor manufacturing, or improper handling. Other factors include accumulated dirt and permanent obstacles like trees or chimneys.

Prevention of Hotspots

- Choose materials from recognized brands with certified manufacturing processes.

- Ensure proper transportation of the modules.

- Follow the manufacturer’s instructions during installation.

- Regularly clean the modules according to site conditions.

- Conduct periodic inspections with specialized equipment.

Delamination

What is Delamination?

Delamination refers to the loss of adhesion between the different layers that make up a photovoltaic module. This defect can appear shortly after installation but may worsen over the module’s lifetime.

Causes of Delamination in a Photovoltaic Module

Delamination is usually associated with poor manufacturing or the use of low-quality materials. Additionally, improper transportation and handling during installation increase the likelihood of delamination. Environmental factors such as temperature, humidity, and UV radiation accelerate this process, especially in lower-quality modules.

Detection and Prevention of Delamination

Delamination can be identified through visual inspection, observing color changes in the module, white spots on the front, or bubbles on the back.

How to Prevent Delamination?

- Purchase materials from trusted brands with certified manufacturing processes.

- Ensure proper transportation, keeping the modules palletized and free from additional weight.

- Handle the modules carefully during installation, following the manufacturer’s recommendations.

- Periodically inspect the plant, performing visual checks and using specialized equipment at least once a year.

How Does Delamination Affect Photovoltaic Modules?

When delamination occurs away from the module’s edge, it can affect performance without posing an immediate safety risk. However, if delamination spreads to the edges, it can allow air and moisture to enter, leading to corrosion and irreversible deterioration of the module, which puts the plant’s integrity at risk.

LeTID Effect (Light and Elevated Temperature Induced Degradation)

What is the LeTID Effect?

The LeTID effect is a phenomenon that affects photovoltaic modules, particularly those using PERC cells. Discovered in 2012, it causes a power loss due to sunlight exposure, similar to LID, but occurs at operating temperatures above 50°C, whereas LID occurs at lower temperatures.

Causes of the LeTID Effect and How It Is Detected

Research points to hydrogen as the main culprit. During the cell manufacturing process, hydrogen atoms diffuse from other layers into the active area of the cell. High temperatures in the manufacturing process increase this diffusion, raising the risk of LeTID.

This issue is not visible to the naked eye, as LeTID is detected through an abnormal drop in panel performance. To confirm it, after ruling out other defects such as hotspots or delamination, electroluminescence equipment is used, just like with LID.

Preventing the LeTID Effect

Manufacturers and laboratories are working to better understand and mitigate the effects of LeTID. Some preventive measures in the manufacturing of PERC cells include:

- Using materials with low hydrogen content.

- Reducing temperatures during cell treatment.

- Using thinner wafers.

What You Need to Know

To prevent the effects of LID, hotspots, delamination, LeTID, or derating, it is crucial to carefully select both materials and manufacturers, optimize wafer treatment processes, and apply proper practices in transportation, installation, and maintenance of photovoltaic modules. Preventing and detecting these defects not only ensures greater efficiency and a longer lifespan for installations, but also provides significant long-term economic benefits.

In conclusion, the photovoltaic industry faces complex challenges that affect the durability and performance of installations. However, by using high-quality materials, applying advanced technologies, and ensuring proper maintenance, it is possible to mitigate these issues and ensure that installations operate optimally. At Azimut360, we work to provide comprehensive, tailored solutions for preventing and detecting these defects, ensuring that our clients’ photovoltaic installations not only maximize their efficiency but also extend their lifespan, generating sustainable economic benefits in the long term.